SMART SOFTWARE

imos iX accompanies manufacturers of furniture and interior furnishings from sales through planning, presentation and construction to production. The branch-specific 3D construction tools are linked with modern machines and new communication platforms. Individual furniture or complex interior design concepts can thus be realized cost-effectively. Detail accuracy and consistency guarantee more safety in the manufacturing process. The modular structure allows for a gradual introduction.

Direct to the Point of Sale

With internet-based presentation and ordering systems, imos iX offers innovative e-commerce solutions, that enable new business models to be mapped.

Solutions along the “Customer Journey”

End customers and designers work together on ideas that can be exchanged online and thus lead successively to finding solutions.

Features

- Web based space planning, presentation and ordering system

- Simple 3D configurator for customizable products

- Augmented reality applications for Android and iOS devices

- HD visuals using cloud based rendering technology

- For multi-channel sales

- Interactive VR

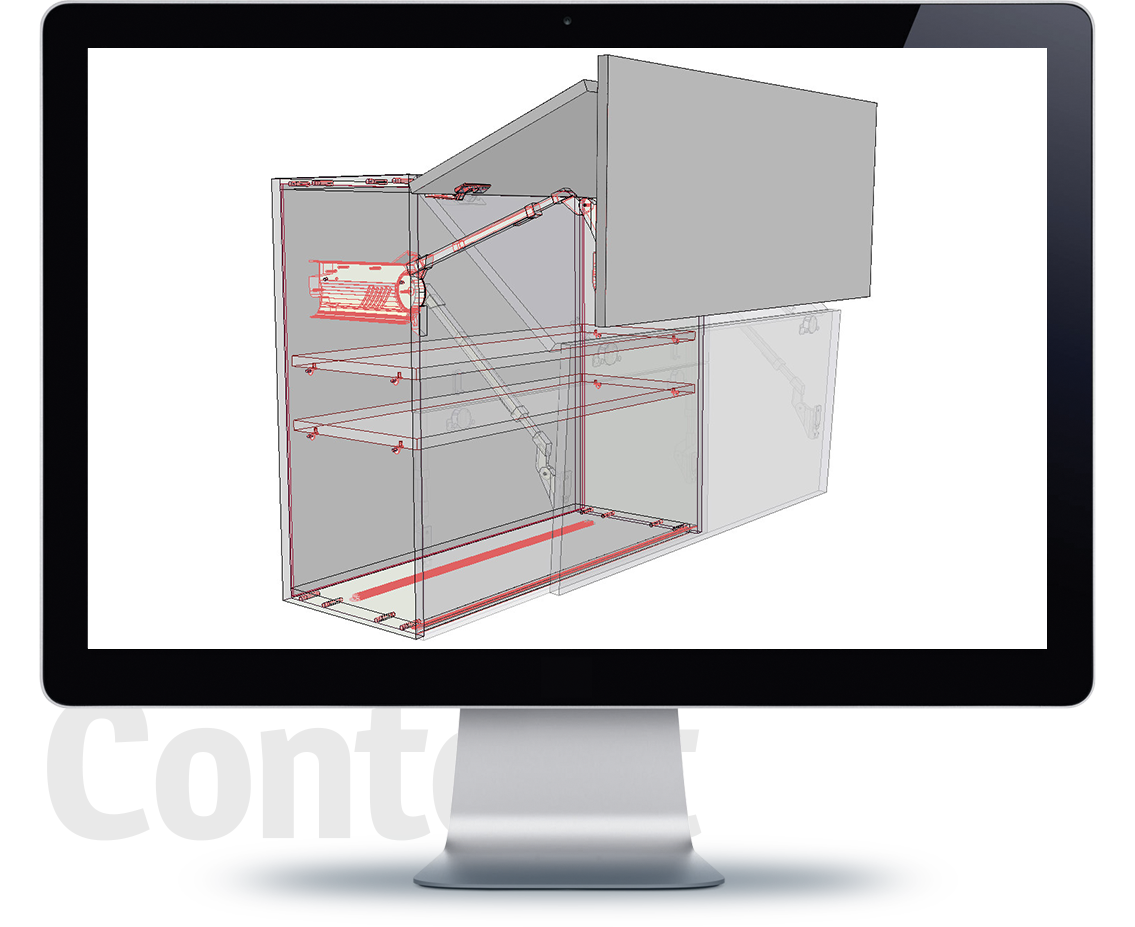

Simple 3D parametric design

Individual furniture or entire room situations can be designed and impressively presented in the shortest possible time. Components are created from materials, coatings, edges and profiles, which are assembled on the screen into furniture and furnishings.

Fast implementation of design changes and revisions

Due to the parametric approach to design, furniture details or entire assemblies can be changed, re-calculated and updated at any time. The relevant setting out, detail and production drawings behave associatively and are re-generated automatically from the modified 3D model. With a mouse click, parts and production list and even CNC data are immediately produced.

Features

- Parametric and free design in iX CAD

- Interactively arrangeable user interface

- Industry-specific design assistants including

- Fast implementation of construction changes

- Intelligent selection and positioning of fittings

- Output of individual cutting and parts lists

- Generation of 2D and 3D drawings

- Photorealism

Directly to the Machine

Completed orders originating from either iX NET, iX PLAN or iX CAD can be sent directly to the CNC machines. From the finalized design, iX CAM automatically generates the CNC programs for all common machine manufacturers – whether an individual CNC machine, an automated workshop center, or a totally networked production plant.

Production Reports and NC data

In addition, the entire production processes are mapped and the CNC data generation adapts to the respective production workflow: easy, fast, secure and economic.

Features

- Production lists and NC data directly from iX CAD

- Control of production systems and CNC machines from industry leading suppliers

- Automatic tool and drill allocation

- Unique part identification using barcode labels

- Efficient 5-axis programming including toolpath simulation

- Multi-machine operations using intelligent workflows

- Special machining strategies for solid wood machining, edge banding on CNC, 5 axis and nesting machines

- Calculation of machining times

- Modifying NC programs without changing the main data

Data Service for Suppliers

iFurn is a data service specially designed to the needs of the furniture industry. Well-known suppliers to the furniture industry place their product data in the cloud via iFurn so that it can be used for furniture design.

Design catalogues available offline and online

The Cloud service supports the CAD designer in the selection and use of materials and fittings. Together with manufacturers and distributors from the furniture supply industry, comprehensive catalogues with intelligent hardware, materials, profiles and fittings are available. These are constantly updated and can be accessed at any time via the Design Catalog or the iFurn data portal.

Features

- Data for the entire supply and production chain

- Only verified original data from the supplier

- Fitting data incl. machining and kinematics information

- Automatic update of fitting data

- Desired products and accessories can be found quickly

- Generic and real animations

Integration of systems instead of additional interfaces

The integration center professionally combines the design and production data from imos iX with external systems such as ERP, MES or sales systems simply, quickly and efficiently. Configuring instead of programming is the rationale here. The data generated by imos iX is transferred to the connected systems for further processing and / or vice versa.

With technology as standard

“iBots” are the integration centers building blocks that can be assembled into various chains that organize and automate the exchange of data between different programs and IT systems. Error logging and monitoring simplifies the implementation of the system with error analysis.

Features

- Data exchange across systems

- Web services for process automation

- Multi-process management

- Process monitoring

- Error logging

- Standardized interfaces (ERP, MES, etc.)